April 9, 2015

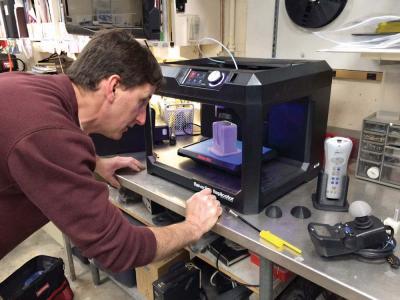

The Boston Home’s Don Fredette works on a project using a MakerBot printer. Photo courtesy TBH

The Boston Home’s Don Fredette works on a project using a MakerBot printer. Photo courtesy TBH

The Boston Home on Dorchester Avenue has recently acquired a 3D printer that is improving every day life for staff and residents. The Boston Home, located near Ashmont Station, is a residence and care center for adults with advanced Multiple Sclerosis and other progressive neurological diseases. Multiple Sclerosis, the disease that affects most of the residents at The Home, targets the brain, spinal cord, and the optic nerves. MS can cause problems with vision, balance, muscle control, and other basic body functions.

After receiving a generous donation to purchase the printer, the Home’s Adaptive Equipment Specialist Don Fredette has been able to create custom devices for any resident that needs them.

3D printers are “really just sophisticated hot glue guns,” Fredette explains with a laugh.

The printer, a MakerBot brand, has on board memory and requires no coding. With it, Fredette has been able to make many tools necessary for life with MS readily available for residents at all times. He has designed cradles for voice-controlled television remotes, chin switches for calling aids, holders for communication devices, cell phones, tablets, and even cup holders for residents’ wheelchairs.

Boston Home resident Pam Kassel has already seen the benefits of a having 3D printer in house. Her Galaxy 5 now has a holder on her wheelchair and her bedside, with magnets attaching her voice control device. She couldn’t be happier with the accessibility these simple gadgets have provided.

“Many residents are intrigued by it. They’re surprised by commonplace technology being used for accessibility, and the peer support they give each other is remarkable,” Fredette said.

The quick nature of the machine makes it possible for Fredette to receive a request, make a template, print the object, and deliver it to the resident in less than a day.

“It was on my wish list as a tool to utilize,” Fredette said. “To me, it’s just another tool in the toolbox. I’m not a designer, and I don’t dedicate all my time to the printer, but it has been much more economical for upgrading wheelchairs and customization for the residents.”

The wheelchairs have been greatly helped by being manufacturing “T-handles” for easier wheelchair control, stylus holders for patients experiencing finger isolation. The ability to tinker with individual cases is indispensable to Don Fredette.

“After I make something with the MakerBot, I can automatically tell what isn’t going to work. It’s great for prototypes. If I’m working with someone in California, and they need my template, I put my file in an email and boom! It’s done! We save so much time.” Don Fredette is grateful to have the 3D printer not only for its printing abilities, but its lessons about The Boston Home as well.

“It’s really helped bring attention to assistive technology, and the work we do here,” he said.

While the printer has been a blessing, it also has its shortcomings. The financial strain of producing aids that aren’t reimbursed by insurance companies have become apparent to Fredette.

“There are certainly hidden costs. For example, the graphics card on my computer is old and causes glitches. I may need a new one.”

But for The Boston Home, making accommodations and maintaining a standard for residents’ needs is a necessary financial commitment.

“Going through Medicare can take months,” Fredette said. “Having already tried 3D printing sometimes justifies our complaints to the insurance company, by showing success in what we’ve manufactured here.” The items Fredette prints also help The Home decide whether or not a particular adaptation is worth investment.

As Fredette said, “With these printers, we can imagine, and then remake; work or retool. The individual nature of the printing is incredibly helpful.”